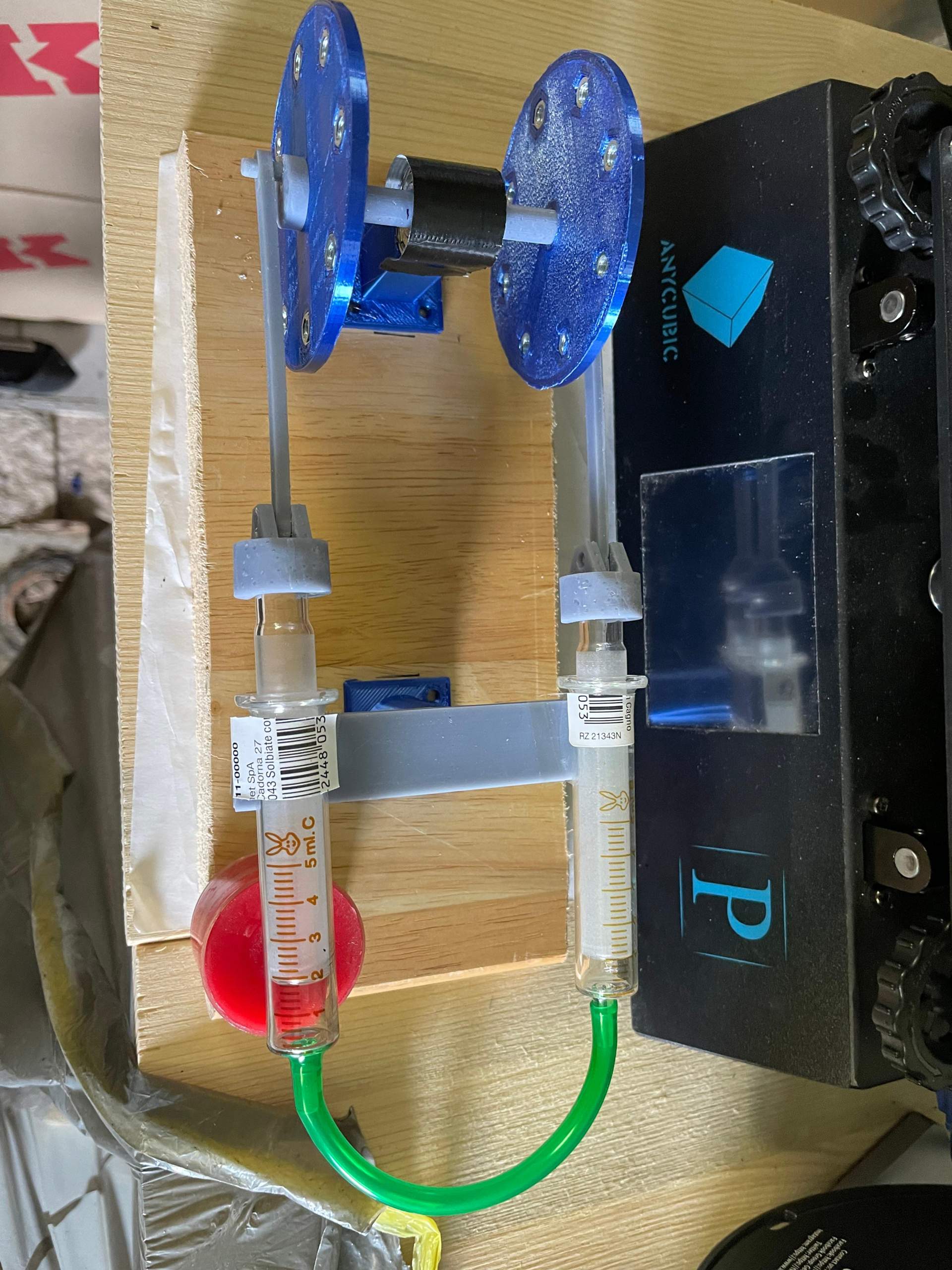

Warum geht mein selbstgebauter Stirling Motor nicht?

Ich habe aus meinem 3d Drucker einen Stirling Motor gebastelt mit verschiedenen Teilen. Allerdings fängt er einfach nicht an los zudrehen. Woran liegt das? Alles ist einigermaßen leichtgehend. Und dicht.

What do you mean “too easy”? A stirling engine in size has only extremely little power, so everything has to go extremely easily so that it even turns.

Perhaps the timing of the two pistons is not entirely correct, i.e. the position of the crank pins on the crankshaft.

It can also be that the flywheel mass is not sufficient

It may help if you make the cold cylinder colder, e.g. with ice cubes.

I hope you realize that a stirling engine does not start by itself, but has to be thrown at, isn’t it? And try in both directions, it can only run in one direction, depending on which cylinder is heated…

He shaft 2-3 turns with an anstupser and starting with myself, of course, I mean turning the flywheel.

how should your eyes be timing? But thanks for the many information

This is dependent on the temperature of the hot cylinder if you would reach extremely high temperatures 90 degrees offset between the crankshaft pins would be ideal, but because your candle flame is definitely not hot enough for this, something between 120 and 170 degrees would probably be useful.

At 90° you can theoretically achieve the maximum power, but very high temperatures are necessary, the greater the angle becomes, the less temperature is necessary, but also less maximum power is generated. At 180°, he wouldn’t work anymore.

You can read this on Wikipedia under Stirlingmotor, there is also a table which is suitable for what application/temperature range, you have the type Alpha, so you have to read the values from the corresponding line …

Thanks a very helpful comment. 👍👍👍

each heat engine lives from a fast heat exchange with the temperature reservoirs, for this you need a good heat conductor, i.e. metal. I don’t see any metal. I also see no heat-conducting regenerator material in the connection between the working pistons, without which a stirling motor cannot function.

The thermal energy that the candle supplies is too low to overcome the frictional resistances in the syringes, in order to express this in a lain-like manner.

This is logical thanks

You know where I’m getting an alcohol candle?

Unfortunately no.

Ok no problem thanks

What’s wrong? Maybe the pistons aren’t sealed enough?

They keep tight, but if I want to start, it doesn’t run off, it’s only moved by my hand.

What kind of gas is in there? Depending on the gas, you need more heat.

Hm, okay.

Then do what others said here. Heat one side more, cool the other more.

Normal air

These are plastic syringes, aren’t they?

The candle will melt this before the air has warmed in it…

Have you ever seen a real Stirling engine?

It’s all made of glass and aluminum – why…

No, it looks like glass spraying for me.

These are naturally glass-spraying.

What is the piston? What are you heating?

You have to heat a metal pipe…

That’s sweet, but I’m coming out of a sleswig-holstein. This is a bit far away 😊 but thanks for the offer

If you live near Rosenheim / Munich, I can show you a real Stirling engine…

You can then explore it…

Yes, that’s true and I even asked my physics teacher and had different sources, but no matter what, I’ll try it out.

Then maybe a gas burner would reach more than the cold candle…

And what you saw was certainly in Youtube…

Such a motor, like the “free energy” engines.. all video mounting – and I also know how this goes…

I’ve seen a lot of things that were exactly the same and worked

The piston is smooth and the piston consists of the counterpart to the syringe. I heat the syringe and not the hose.